Understanding cement slab price in plain language

Homeowners are often surprised when two quotes for the same size slab come back very different. You might see a big gap even when both contractors measured the same area. Here is the simple truth. The cement slab price is driven by far more than square footage. Site prep, thickness, reinforcement, concrete mix, finish level, access, and local codes all combine to shape the final number. In this guide, Custom Concrete & Stone Design explains the major factors that push costs up or down, and how to estimate a fair price for your Milwaukee or Southeast Wisconsin project.

The short list: what affects cement slab price the most

- Site conditions and preparation

- Slab thickness and engineering needs

- Reinforcement type and spacing

- Concrete mix strength and additives

- Forming complexity and slab shape

- Finish level, color, stamping, and sealing

- Access, staging, and equipment needs

- Drainage, slope, and frost protection

- Permits, inspections, and local code requirements

- Demolition, haul away, and disposal of existing concrete

Same size does not mean same scope

Two patio slabs can both measure 12 by 20 feet, yet require different amounts of material, labor, and equipment. Volume matters, not just area. A 4 inch slab uses far less concrete than a 6 inch slab. A curved patio with steps and decorative borders takes more time than a simple rectangle. A driveway that must support heavy trucks needs stronger engineering than a garden shed pad. The cement slab price reflects the full scope, not just length times width.

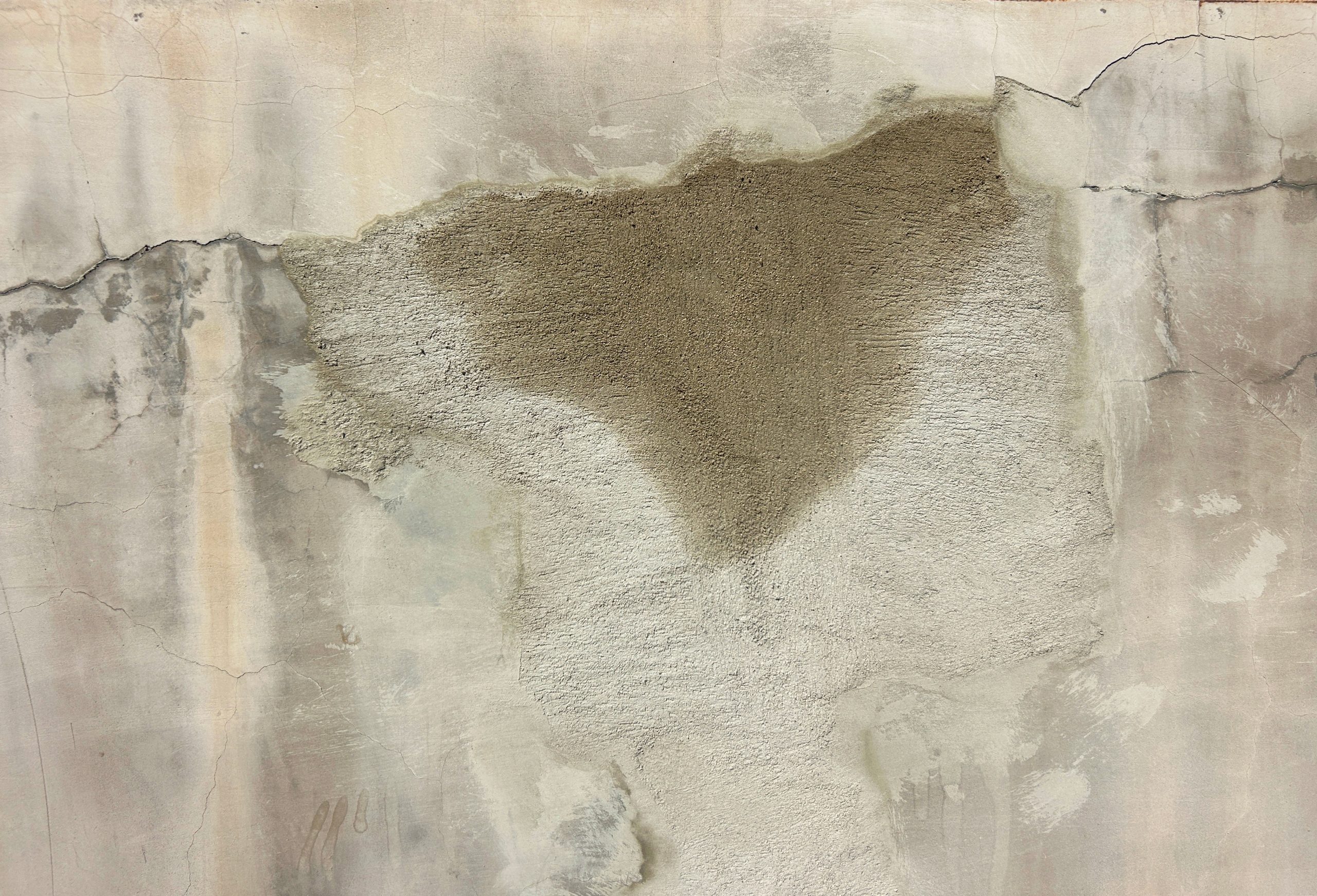

Site preparation is the foundation of the price

Every slab sits on soil and base material. The quality of that foundation determines how long the slab lasts. It also drives cost. Proper site prep prevents settlement, heaving, and cracking. Custom Concrete & Stone Design always evaluates soil conditions, water movement, and the strength of the base before proposing a solution.

Soil quality, base stone, and compaction

Soft or organic soil must be removed and replaced. Most slabs need several inches of graded base stone that is compacted in lifts. In Southeast Wisconsin, we often use crushed stone that locks together under compaction. More base is required for weak soils, driveways, and garage floors. Good compaction requires the right moisture content and the right equipment. The labor and materials involved add to the cement slab price, but they protect your investment by preventing failures later.

Demolition and haul away

If there is old concrete or asphalt in place, it must be broken up, loaded, and disposed of. Thicker or reinforced concrete takes more time to remove. Tight sites can require smaller equipment and more labor. Disposal fees also vary by county. This step alone can create a major difference between two prices for the same size slab.

Drainage, slope, and water management

Slabs must shed water away from your home and toward approved drainage paths. Correct slope protects basements, garages, and foundations, and keeps ice from forming in winter. If water pooling is a risk, the crew may add drains, swales, or extra grading. These details are small on paper but big for long term performance. They often explain why one cement slab price includes more site work than the other.

Thickness and engineering needs

Thickness is one of the most important drivers of cost. It affects concrete volume, labor, and reinforcement requirements. It is also tied to the loads the slab must carry. Custom Concrete & Stone Design recommends thickness based on use, soil strength, freeze-thaw exposure, and local codes in Milwaukee, Waukesha, Ozaukee, Washington, Racine, and Kenosha counties.

4 inches vs 5 inches vs 6 inches

Many patios and walkways use a 4 inch slab. Driveways and garage floors often require 5 or 6 inches, especially if heavy vehicles or trailers will park on them. A thicker slab can reduce cracking and improve long term durability. It also requires more concrete and time, which raises the cement slab price. This is why two 12 by 20 slabs can be priced very differently if they serve different purposes.

Thickened edges and footings

Some projects need thickened edges or integral footings. A shed slab may need thickened edges to resist frost heave. A support column might require a footing pad. These upgrades are not visible once the slab is poured, yet they are vital. They add excavation, formwork, and concrete volume. Any quote that includes them will be higher but also more likely to pass inspection and stand up to Wisconsin winters.

Reinforcement choices change cost and performance

Reinforcement helps control cracking and improves load capacity. The type and amount used has a clear effect on price and results.

Rebar, welded wire mesh, and fibers

Rebar offers strong crack control and is common for slabs that carry heavy loads. Welded wire mesh provides lighter reinforcement for general use. Fiber reinforcement mixes synthetic fibers into the concrete to help control micro cracking and surface durability. Many slabs use a combination of rebar and fibers. More steel, tighter spacing, and extra chairs or supports cost more, yet provide better performance. The right design depends on use and site conditions.

Concrete mix design and seasonal additives

Concrete is not one-size-fits-all. Mix strength, air content, and additives must match the project and the season. In Southeast Wisconsin, freeze-thaw cycles, de-icing salts, and temperature swings make mix selection important. Custom Concrete & Stone Design tailors mix specs to the job rather than using a generic recipe.

PSI, air entrainment, and cold or hot weather needs

Slabs for driveways or garages often use higher compressive strength mixes. Air entrainment helps concrete survive freeze-thaw cycles. In cold weather, accelerators and heated water can help concrete set properly. In hot weather, workability and curing require adjustments. These upgrades can add cost, yet they protect against scaling and premature wear. If one bid includes a high quality mix and one does not, the cement slab price will not be comparable.

Forming, layout, and slab shape

Simple rectangles are faster to set up. Curves, tapers, and cutouts take more time. Steps, risers, and borders add complexity. Tight property lines or landscaped areas can require custom formwork. Choosing a design that fits your space and your budget is key. Custom Concrete & Stone Design specializes in clean layouts that reduce waste and improve curb appeal, which can stretch your dollars further.

Edges, borders, and steps

Thickened edges, decorative borders, and integrated steps add curb appeal and utility. They also add formwork, finishing effort, and sometimes rebar. A basic slab with straight edges is less expensive than a slab with rounded corners and an integral step. If the look matters, budget for these features during the planning phase.

Finish level and decorative options

Finishing steps affect both appearance and durability. A basic broom finish costs less than a stamped, colored, or exposed aggregate finish. Sealing adds protection from moisture, stains, and de-icing chemicals. Your desired look and maintenance plan will shape the cement slab price.

Broom, trowel, stamped, colored, and sealed

Broom finish provides traction and is common for exterior slabs. Trowel finishes are smooth and often used indoors. Stamped concrete mimics stone or wood and boosts curb appeal. Integral color, acid stains, and release agents add depth and character. Sealing locks in color and slows water and salt penetration. Each upgrade adds cost but also adds value. Custom Concrete & Stone Design is known for stamped and decorative work throughout Southeast Wisconsin, and we can align finish choices with your budget.

Access, staging, and equipment

How easy is it to get concrete and equipment to your pour location? If the truck cannot reach, concrete may need to be pumped or moved by buggy. Hills, tight gates, and long carries add time. If heavy equipment would damage landscaping, we may need protective mats. Access challenges often explain why one cement slab price is higher. Good planning can reduce this cost.

Frost, control joints, and crack management

Every slab needs a plan to control cracking. Proper base and compaction, reinforcement, control joints, and curing all work together. Control joints are saw cuts or tooled grooves that guide where cracks form. In cold climates, joint spacing and timing matter. Saw cutting at the right time takes skill and extra visits. A thorough bid includes this step because it protects the slab for years.

Permits, inspections, and local codes

Cities and villages in Milwaukee, Waukesha, Ozaukee, Washington, Racine, and Kenosha counties may require permits, setbacks, and inspections. Garage slabs, foundations, and retaining wall footings often have specific rules. Compliant work may require thicker sections, vapor barriers, or specific reinforcement. A quote that covers permit support and code compliance can look higher, yet it saves headaches and ensures your project passes inspection the first time.

Two “same size” slabs, two very different prices

Consider two 12 by 20 foot slabs. Both are 240 square feet. The first is a backyard patio with easy access. The soil is firm and dry. The slab is 4 inches thick with fiber reinforcement and a simple broom finish. Minimal grading is needed and no old concrete is on site. The second slab is a driveway extension at a home on a narrow city lot. Access is tight and a pump is needed. The slab is 6 inches thick with rebar on a 24 inch grid. The crew must remove old concrete and haul it away. The site needs extra base and careful compaction. Control joints and sealing are included for long term durability. Both are 240 square feet, yet the materials, labor, and equipment are very different. The second project will cost more because it must support heavy loads, meet stricter performance needs, and handle demolition and access limits. The cement slab price reflects these realities, not just square footage.

How to estimate your cement slab price

You can build a rough estimate by thinking through use, thickness, site prep, and finish. While only a site visit can produce a firm quote, the steps below help you understand what to expect.

Step-by-step planning

- Define use. Patio, walkway, driveway, garage floor, basement, shed pad, or foundation.

- Choose thickness. 4 inches for light use, 5 to 6 inches for driveways or heavy loads.

- Assess site. Soil strength, water flow, slopes, trees, and access routes.

- List prep tasks. Excavation depth, base stone thickness, compaction plan.

- Select reinforcement. Fiber, mesh, rebar spacing, or a combination.

- Pick a finish. Broom, trowel, stamped, colored, exposed aggregate, sealing.

- Check code and permits. Confirm local requirements for your municipality.

- Plan joints and curing. Joint layout and curing method to control cracking.

- Account for extras. Steps, borders, drains, thickened edges, or radiant heat.

- Get local quotes. Ask for a detailed scope so you can compare apples to apples.

Questions to ask any concrete contractor

- What slab thickness and reinforcement do you recommend for my use and soil?

- How much base stone and compaction will you include?

- What concrete mix strength and air entrainment will you use for our climate?

- How will you manage drainage and protect my home foundation?

- What is the control joint layout and timing of saw cuts?

- What is included for curing and sealing?

- How will access be handled? Is a pump or buggy required?

- Who handles permits and inspections if needed?

- What is your plan for weather delays to protect quality?

- Can you provide local references and photos of similar work?

Ways to balance budget and quality

- Keep the slab layout simple and rectangular if design allows.

- Use decorative borders only where they have the most visual impact.

- Choose fiber plus strategic rebar instead of full mesh coverage when appropriate.

- Plan access early to avoid last-minute equipment needs.

- Schedule during normal work hours to avoid rush or after-hours premiums.

- Invest in proper base and compaction. It is the best long term value.

Why homeowners in Southeast Wisconsin choose Custom Concrete & Stone Design

Custom Concrete & Stone Design has delivered concrete craftsmanship across Milwaukee and Southeast Wisconsin for over 30 years. Our team designs and installs stamped concrete, driveways, patios, retaining walls, garages, basements, and foundations built for our climate. We serve Milwaukee, Waukesha, Ozaukee, Washington, Racine, and Kenosha counties. We combine high quality materials with skilled crews who care about the details that matter.

Our process focuses on your goals and your site

Every project starts with a careful site review. We evaluate soil, drainage, access, and usage so your slab performs for the long run. You will receive a clear scope that explains thickness, reinforcement, mix design, joint layout, and finish selections. We coordinate permits when required. We set expectations for schedule and weather protection. By the time we pour, you will know exactly what you are getting and why it is the right solution for your property.

Frequently asked questions about cement slab price

Why do quotes vary so much for the same size slab?

Because square footage only tells part of the story. Differences in thickness, reinforcement, base stone, site prep, access, finishes, and code compliance can all shift the cement slab price for the same footprint.

Is a thicker slab always better?

Thicker can be stronger, but it must match your use and soils. Overbuilding in the wrong place wastes money. Underbuilding invites cracks and settlement. The best choice balances performance and value.

What is the best reinforcement for my slab?

It depends on use, loads, and soil. Fiber helps control micro cracking. Mesh offers light reinforcement. Rebar adds strength and crack control for heavier loads. Many jobs use a combination. A site visit will guide the choice.

Do I need a permit for my slab?

Some municipalities require permits for driveways, garage floors, and structural slabs. Requirements vary across Milwaukee, Waukesha, Ozaukee, Washington, Racine, and Kenosha. Custom Concrete & Stone Design can help you confirm what is needed.

How can I avoid cracking?

All concrete cracks. The goal is to control where and how. A proper base, correct thickness, reinforcement, good drainage, well placed control joints, and careful curing all work together to produce a strong, attractive slab.

Does finish affect durability?

Yes. A quality broom finish with proper curing and sealing stands up well outdoors. Stamped and colored finishes add beauty and require sealing to protect against moisture and salts. The right finish for your use will balance appearance and durability.

The bottom line on cement slab price

When you compare quotes, ask for details. If two bids differ, the scope likely differs too. Look beyond size to see thickness, reinforcement, base prep, mix design, finish level, and access. In Southeast Wisconsin, successful slabs must also account for freeze-thaw cycles and drainage. Custom Concrete & Stone Design builds these factors into our recommendations so you know your investment is protected. With the right plan and a skilled crew, your slab will look great on day one and perform for years to come.

Plan your project with confidence

If you want a clear, apples-to-apples proposal, invite Custom Concrete & Stone Design to review your site. We will listen to your goals, measure carefully, and explain each cost driver before we pour a single yard. That way, the cement slab price makes sense, and the finished slab meets your needs in every season.