Why truck dock concrete repair matters more than you think

When trucks pound your dock day after day, small cracks can turn into serious problems. Damaged concrete around a loading area is more than an eyesore. It creates safety risks for drivers and dock workers. It can slow your operation and even shut it down. Truck dock concrete repair keeps your team safe, protects your equipment, and reduces costly disruptions. If you manage a warehouse, distribution center, or manufacturing facility in Southeast Wisconsin, this topic should be high on your list. The sooner you act, the more you save.

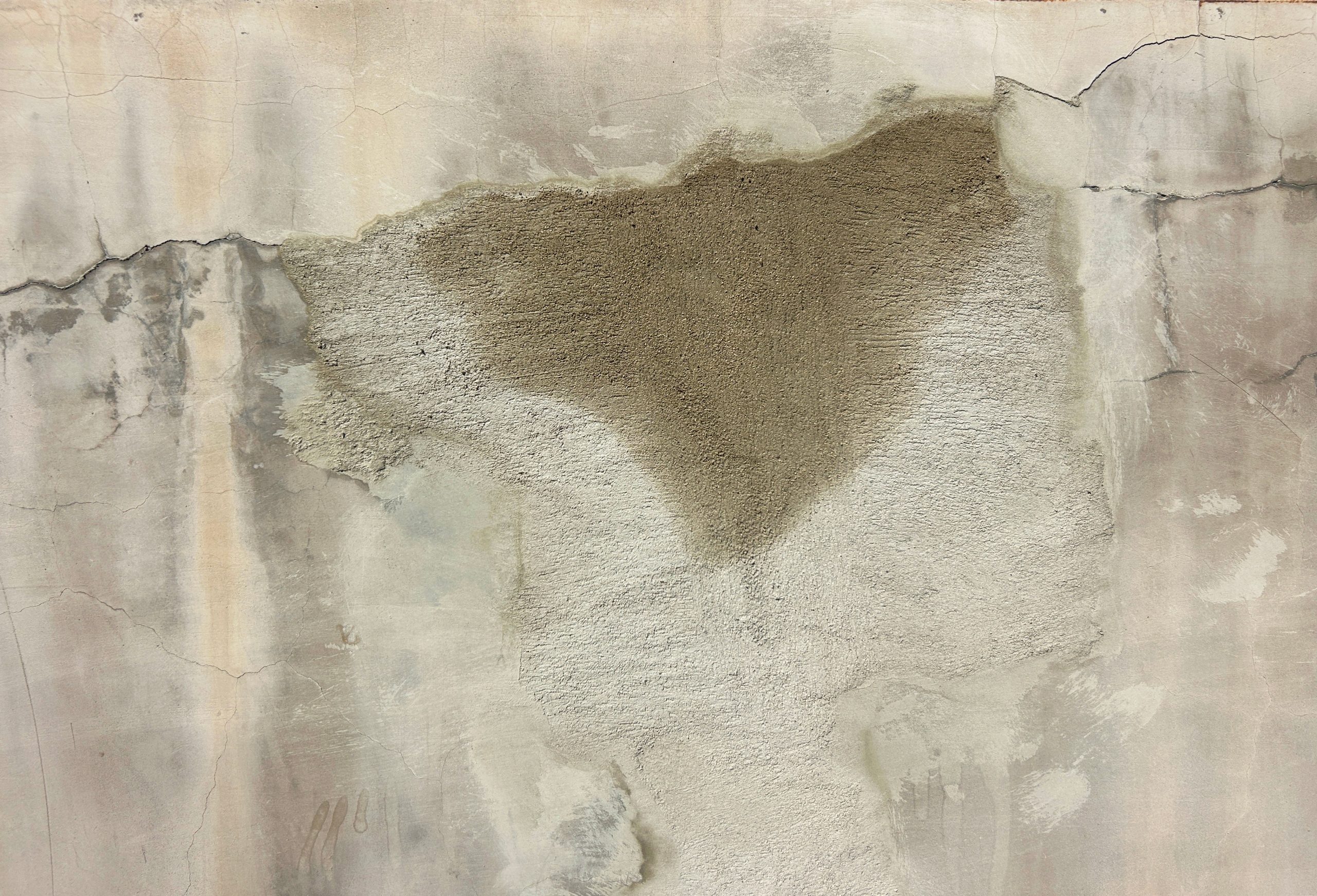

At Custom Concrete & Stone Design, we see the same pattern over and over. Tiny surface cracks become spalls and potholes. Uneven slabs create trip hazards and hard stops for pallet jacks. Joint edges break down under wheel loads. Water gets into the base and makes everything worse during freeze and thaw cycles. With over 30 years of experience, our team knows how to stop the damage before it becomes a major rebuild. A free inspection can help you understand what is happening and what to do next.

How concrete at loading docks gets damaged

Truck docks face harsh conditions. The apron, approach, and leveler pits absorb constant impacts. Even the best concrete needs maintenance. Understanding the causes helps you plan the right truck dock concrete repair at the right time.

- Heavy wheel loads from trailers, forklifts, and pallet jacks

- Impact at the dock face and leveler lip

- De-icing salts and chemicals that attack concrete

- Water infiltration that freezes and thaws

- Inadequate joint protection or failed joint sealants

- Poor drainage that keeps water under the slab

- Aging concrete or improper original construction

Each of these stresses leads to different types of failures. That is why a one-size-fits-all fix often does not last. A targeted truck dock concrete repair plan treats both the visible damage and what is causing it.

Signs you should not ignore

Walk your dock area and look for these early warnings. Addressing them now will prevent bigger repairs later.

- Cracks that run across wheel paths or expand at joints

- Spalling or pitting where the surface flakes away

- Pumping at joints where fines squirt up when traffic rolls over

- Uneven slab edges or sunken sections that cause bumps and trips

- Standing water near the dock face or leveler pit

- Rust staining near rebar or dowel locations

- Loose joint material or gaps where sealant has failed

Any of these conditions can turn into a safety hazard. Fast action with the right truck dock concrete repair methods will protect your team and your schedule.

What a professional truck dock concrete repair includes

Repair work should begin with a clear picture of the damage and the causes. Custom Concrete & Stone Design follows a proven process to deliver lasting results for commercial docks across Milwaukee, Waukesha, Ozaukee, Washington, Racine, and Kenosha counties.

- Site inspection and assessment of the apron, approach, dock face, and leveler pit

- Moisture and drainage review to find water sources and freeze risk

- Joint condition evaluation to determine load transfer and sealant issues

- Repair recommendations focused on safety and downtime reduction

- Clear schedule planning to keep your operations running

- Quality repairs using top materials and skilled craftsmanship

- Final walkthrough with maintenance tips to extend the life of your dock

This approach ensures your truck dock concrete repair supports both safety and productivity. We measure success by how smoothly your team can work the next day and the next season.

Repair methods we use to restore your dock

Every loading dock is different, so we mix and match solutions based on what we find. The goal is always the same. Make the area safe, strong, and ready for heavy traffic.

Crack routing and sealing

For tight cracks that have not shifted, we route and seal the cracks with high performance materials. This keeps water and chemicals out. It also prevents further expansion during freeze and thaw cycles. This step is often the first line of defense in truck dock concrete repair.

Joint rehabilitation and load transfer fixes

Open or broken joints let slab edges chip away under wheel loads. We clean and replace joint sealants and repair damaged edges. If needed, we restore load transfer with dowels or retrofit load transfer devices. This stabilizes traffic paths and stops further breakdown.

Spall and pothole patching

Surface breakdowns and potholes are common near the dock face and leveler lip. We remove weak concrete, prepare the area, and place rapid strength patch material. Where heavy impacts are common, we use durable mixes designed for industrial use. The result is a smooth surface that stands up to forklifts and trailer wheels.

Epoxy injection for structural cracks

When cracks go deep or impact the structural reliability of the slab, we use epoxy injection. This method bonds the concrete back together and stops water intrusion. Our team evaluates when injection is the right fit versus when removal and replacement is better.

Slab replacement in critical zones

Sometimes the damage is too advanced for surface repair. In those cases we cut out and replace the affected panel or apron section. We make sure the base is compact, the thickness is correct, and the reinforcement is right for your traffic loads. Custom Concrete & Stone Design uses high quality concrete mixes and curing methods to ensure a long service life.

Slab jacking or re-leveling

If a slab section has settled, we can lift and re-level it with grout or foam injection. This brings the surface back to grade and removes trip points. It also restores proper drainage away from the building and leveler pit.

Surface protection and sealing

Once repairs are complete, we often apply a penetrating sealer or surface treatment. This helps resist salt, water, and chemicals. Preventive sealing is a smart part of long term truck dock concrete repair planning.

Safety benefits you can see right away

Well executed repairs reduce risk and improve workflow. The effects show up fast in your day-to-day operations.

- Fewer trip hazards for dock crews

- Smoother forklift travel that reduces product damage

- Less impact stress on dock levelers and equipment

- Better traction where water used to collect

- Improved visibility of joints and work areas

Most important, your team can focus on the job instead of dodging hazards. Truck dock concrete repair is one of the simplest ways to raise safety standards.

Reduce downtime and extend the life of your dock

Fast repairs save you time and money. They also protect your building investment. By addressing damage early, you avoid shutdowns for major reconstruction. Our crews at Custom Concrete & Stone Design plan work windows around your shipping schedule. Many repairs can be phased to keep lanes open. We help you rebuild the right sections and avoid paying for work you do not need.

Costs and return on investment

The cost of truck dock concrete repair depends on the size of the area, the type of damage, and the chosen methods. Small cracks and joint resealing are affordable and quick. Deep spalls, slab jacking, and panel replacements cost more but restore long term performance. Either way, the return is strong. You reduce injury risk, equipment wear, and forklift maintenance. You avoid downtime and product loss. You also protect against water infiltration that can damage your building and foundation. A free inspection from Custom Concrete & Stone Design will provide a clear scope and budget so you can plan with confidence.

Wisconsin weather and timing your repairs

Milwaukee area docks face freeze and thaw cycles that can tear concrete apart. Water seeps into small cracks and expands when it freezes. Salt and de-icing chemicals speed up surface damage. The best time for major repairs is during warmer months when materials cure as designed. That said, our team uses cold weather repair methods when needed to keep your dock safe. Preventive sealing before winter is a smart step. For lasting results, plan your truck dock concrete repair with the seasons in mind.

Why facilities across Southeast Wisconsin choose Custom Concrete & Stone Design

Choosing the right contractor makes all the difference. Custom Concrete & Stone Design has served Milwaukee, Waukesha, Ozaukee, Washington, Racine, and Kenosha for more than 30 years. We combine commercial know-how with a commitment to customer care. Our team uses top quality materials and proven techniques. We assign skilled craftsmen who understand heavy traffic environments. We deliver clean, safe work zones and clear communication from start to finish.

Beyond docks, we install and repair concrete driveways, patios, retaining walls, foundations, basements, garages, and stamped concrete. This broad experience helps us handle complex site conditions and unique designs. Every job is customized to your facility needs. When you call Custom Concrete & Stone Design, you get a partner who stands behind the work.

Our simple process for truck dock concrete repair

- Free inspection: We walk your dock, evaluate risks, and listen to your goals.

- Detailed plan: You receive a clear scope, timeline, and pricing with no surprises.

- Phased scheduling: We work around your shipping windows to reduce disruption.

- Quality repairs: Skilled crews install durable fixes that meet heavy use demands.

- Final check: We inspect the work with you and provide maintenance guidance.

This process keeps your project on time and on budget. It also ensures the repairs last through seasons of hard use.

Maintenance tips to extend dock life

Regular care reduces the need for major repairs and protects your investment. These simple steps help keep your dock safe and functional.

- Inspect joints and cracks each quarter and after winter

- Keep drains and gutters clear to move water away fast

- Sweep away sand and salt to reduce surface abrasion

- Re-seal joints before they fail and gaps widen

- Address ponding water and low spots early

- Train crews to report surface changes right away

When you pair good maintenance with timely truck dock concrete repair, your dock will serve you longer and cost less to operate.

Common questions about truck dock concrete repair

How fast can repairs be done?

It depends on the scope. Crack sealing and joint repairs can often be completed in a day. Larger spall patches and slab jacking may take a few days. Panel replacements require more time for curing. We plan work in phases to keep you moving.

Will the repaired areas match the existing concrete?

New patches and panels can have a different color at first. Over time, exposure and wear help them blend in. Our focus is on performance, smooth transitions, and clean edges. Where aesthetics matter most, we discuss options to give a closer match.

Can you work while the dock is active?

Yes. We coordinate with your team to keep freight flowing. We can close one lane at a time, schedule off hours, or use fast setting materials to reopen areas quickly.

How do I know if I need replacement instead of patching?

If the slab is rocking, the base is pumping, or cracks go through the full depth, replacement may be the best solution. Our free inspection will include core reasons for the damage and a clear recommendation.

What about the leveler pit and dock face?

We repair concrete around leveler pits, bumpers, and dock faces. These high impact zones need strong materials and careful detail work. Proper anchoring and edge protection extend the life of these areas.

What sets our craftsmanship apart

Commercial concrete work at a loading dock is not the same as a sidewalk fix. It needs the right mix design, reinforcement, joints, and curing. Custom Concrete & Stone Design brings decades of field experience to every project. We select materials that resist salt and abrasion. We cut clean joints and restore load transfer. We compact the base and manage drainage. Every detail supports the long term strength of your dock.

Ready to stop cracks from becoming safety hazards

Do not wait for the next incident or shutdown. Schedule a free inspection and get a plan you can trust. Custom Concrete & Stone Design is ready to assess your dock and deliver professional truck dock concrete repair that keeps your operation safe and efficient. We serve Milwaukee and the surrounding counties with reliable service and clear communication.

Call Custom Concrete & Stone Design today to protect your team, your equipment, and your schedule. Ask for your free inspection and estimate. Together we will turn today’s cracks into tomorrow’s confidence.

A final note on safety, savings, and service

Every day your dock sees heavy action. When the concrete starts to fail, the risks rise fast. Truck dock concrete repair is a practical step that pays back in safety, uptime, and lower long term costs. With a trusted partner like Custom Concrete & Stone Design, you get the right repairs at the right time. Our team has spent more than 30 years helping facilities across Southeast Wisconsin move freight safely and efficiently. Let us help you do the same.